No rechargeable lithium-ion battery currently used in electric vehicles can function without lithium and cobalt. More than 45 percent of the world’s cobalt and 65 percent of its lithium are currently used to develop mobile energy storage systems. For manganese and nickel, steel production remains the primary application. Lithium-ion batteries require less than 10% of global production. This situation begs the question: Are sufficient raw materials available for energy transition technologies? Since recycling lithium batteries plays a minimal role, the demand must be met almost exclusively with primary raw materials.

Common lithium-nickel-manganese-cobalt oxide rechargeable batteries require approximately 100 grams of lithium, 530 grams of nickel, 160 grams of manganese, and 180 grams of cobalt per kilowatt-hour of power. Based on the average power of the motors and the number of electric cars, which the International Energy Agency predicts will reach approximately 230 million worldwide by 2030, it would be possible to calculate the raw material requirements and theoretically compare them with known reserves and resources. However, those who choose this calculation method commit a grave error since the known reserves are not a fixed quantity. They are always merely a snapshot of a reserve-resource system that develops dynamically.

Resources versus Reserves

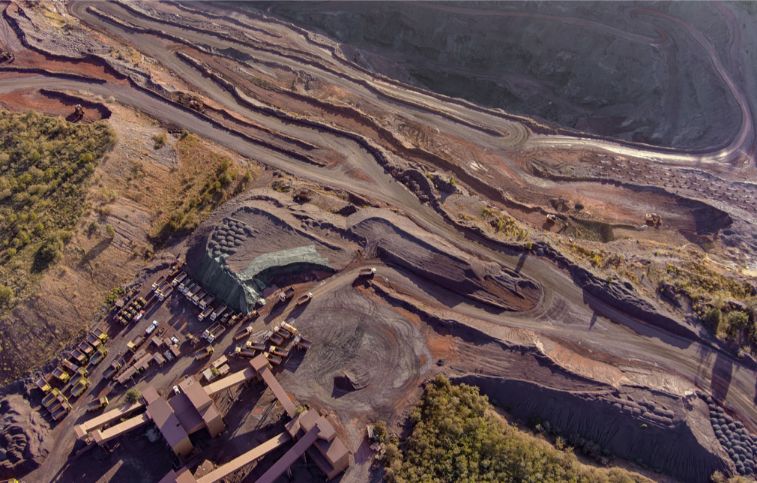

Mineable or potentially mineable raw material deposits are distinguished between reserves and resources. Under current conditions, reserves are economically extractable. On the other hand, resources are known deposits of raw materials, but they are too expensive to extract at current market conditions. Profitable extraction requires higher market prices or new technologies. Furthermore, there is a second category of resources, which are deposits that still need to be sufficiently explored. However, this last category makes up only a small portion of the available raw materials. The taxonomy of reserves and resources is the result of mining companies’ exploration efforts. According to their 30- to 50-year planning horizon, these companies are searching for reserves to begin mining as soon as possible. Reserves and resources that may not be extracted for the next one hundred or two hundred years are quickly disregarded.

Because of this, there are no reasonably accurate estimates of the number of reserves and resources in the world. Instead, we utilize the term geopotentials. Geopotentials are deposits that were previously unknown. However, additional deposits will likely be discovered through exploration due to geological conditions always changing. Geopotentials are estimated to be enormous because innovative techniques and brilliant, out-of-the-box ideas always result in tremendous exploration successes.

Copper

Consider copper as an illustration of a dynamic reserve-resource system. As an essential material for power lines, copper has a unique role in the energy transition. In 1970, global copper production was approximately 6.4 million tons. In 2020, that number reached 20.6 million tons, a 3.2-fold increase. During this time, 613.6 million tons of copper have been extracted, nearly double the 308 million tons of reserves known in 1970. During the same time frame, the known reserves of this non-ferrous metal increased to 880 million tons. Added to this are resources estimated to be approximately 2.4 times the current reserves in 2015. As paradoxical as it may sound, reserves increase together with the demand for materials. This increase happens because mining companies strive to balance their reserves with what they produce. Mining companies’ exploration and research departments can utilize the vast reservoir of known resources and as-yet-unknown geopotentials by employing technological advancements and discoveries.

Lithium

Now, let’s examine lithium, for which particularly high growth rates are anticipated. Many need to understand that the ratio of reserves to production is utterly meaningless, as is evident in the case of lithium. The ratio does not refer to the reserves’ longevity. Instead, a typical ratio is determined for each raw material by geology, deposit type, the regularity or irregularity of the deposits, exploration intensity, or mining company planning. For instance, for manganese, the ratio is approximately 70. For cobalt, approximately 60. For copper and nickel, the ratio is approximately 40, and for zinc, between 20 and 25, with no shortages ever occurring. The number for lithium is well over 100, but the ratio fluctuates widely. In the case of the remaining raw materials, the growth of demand and the expansion of reserves through exploration are proceeding in tandem.

Because of this, their ratios only fluctuate within a relatively narrow corridor. In contrast, the range of fluctuation for lithium is significantly greater. Exploration for lithium fell behind due to unstable growth in demand for the metal. In 2015, the ratio of lithium reserves to production was 438; in 2018, it was 177; and in 2020, it will be back up to 253. While the production figures are derived from official statistics, a team of experts from the United States Geological Survey researches and publishes the most reliable reserve figures annually for the most diverse raw materials.

In addition to being economically viable, reserves must be able to be extracted in an environmentally and socially responsible manner. Water is of utmost importance for some lithium production, whereas for cobalt, small-scale artisanal mining is the best option. The mining processes for lithium and cobalt are similar. Both raw materials are extracted from two distinct types of deposits, and a single nation dominates production in each case. Australia holds 52% of the lithium reserves, while the Democratic Republic of the Congo (DRC) holds 70% of the cobalt reserves. As in Australia, two-thirds of lithium is extracted from pegmatites. The remaining one-third comes from salars (salt lakes in basins without drainage) in which geothermal solutions have concentrated lithium. This deposit is especially prevalent in the arid north of Chile, making this South American nation the second-largest lithium producer with a 26% share of global production. Since 200 to 1,000 cubic meters of brine must be extracted from the salars to produce one ton of lithium carbonate, lithium production in this arid region disrupts the delicate balance of the regional water table.

Cobalt

The Congo provides cobalt for battery production from deposits comparable to the German copper shale at the foot of the Harz Mountains. However, the deposits are considerably older, stronger, and wealthier. In the DRC, approximately one-tenth of the cobalt is extracted by small-scale artisanal miners, whose output is highly price-dependent. Child labor and workplace safety are crucial issues in these small-scale mines. Since cobalt is the most expensive raw material in lithium-ion batteries, automobile manufacturers are attempting to reduce or eliminate cobalt for economic reasons. However, it would be appropriate to consider whether our massive efforts to reverse the energy crisis cannot be combined with efforts to provide emerging countries with development opportunities. Small-scale mining is often the only significant economic factor for poor populations. This sector is estimated to employ up to 150,000 individuals in Congo. In addition, methods for establishing legal and accountable supply chains in small-scale mining can be improved to benefit local populations.

However, more is required to equate geological availability to market availability. Geological availability necessitates timely investments in mining and processing capacities and the timely issuance of permits. Mining projects will always suffer from bottlenecks, and consequently, materials will see significant price fluctuations. These price fluctuations are necessary for the economy to respond following the supply of raw materials. Price spikes motivate individuals to invest in new mines, mine deposits with lower content, utilize less material, and promote recycling.